LCA & material health results & interpretation CAFCO® 300, 300 AC, 300 HS & 3000

Scope and summary

- Cradle to gate

- Cradle to gate with options

- Cradle to grave

Application

The CAFCO® 300 Series is a durable, gypsum based, wet mix, commercial density Spray-Applied Fire Resistive Material (SFRM) designed to provide fire protection to concealed floor and roof assemblies, steel beams, columns, and joists in building construction projects.

Declared unit

1,000 kg of spray-applied fire resistive material, packaging included.

Manufacturing data

Reporting period: January 2017 – December 2017

Location: Stanhope, NJ; Houston, TX; San Bernardino, CA

The amount of water required to be added during the mixing and application of 1,000 kg of dry product is 429 gallons. This water consumption will cause additional environmental impacts in the use phase, which is out of the scope of this assessment.

Default manufacturing scenarios

Production for the product series includes a Kraft paper bag for packaging. At the end of production, approximately 10% of vermiculite is sent to land fill when it does not “pop” in the manufacturing process. Vermiculite is used as a bulking agent in the production process.

What’s causing the greatest impacts

All life cycle stages

The transportation stage dominates the results for all impact categories except for acidification, respiratory effects, and smog where the material acquisition stage dominates. Following these two stages, the lowest impacts come from come from manufacturing stage.

Transportation stage

The impact of the transportation stage is mostly due to the calcium sulfate and vermiculite distances. These two raw materials have the greatest distances of the raw materials.

Sensitivity analysis

There are different raw material weights required for each product in the series. The different material weight directly affect the transportation, production, and end of life impacts.

Multi-product weighted average

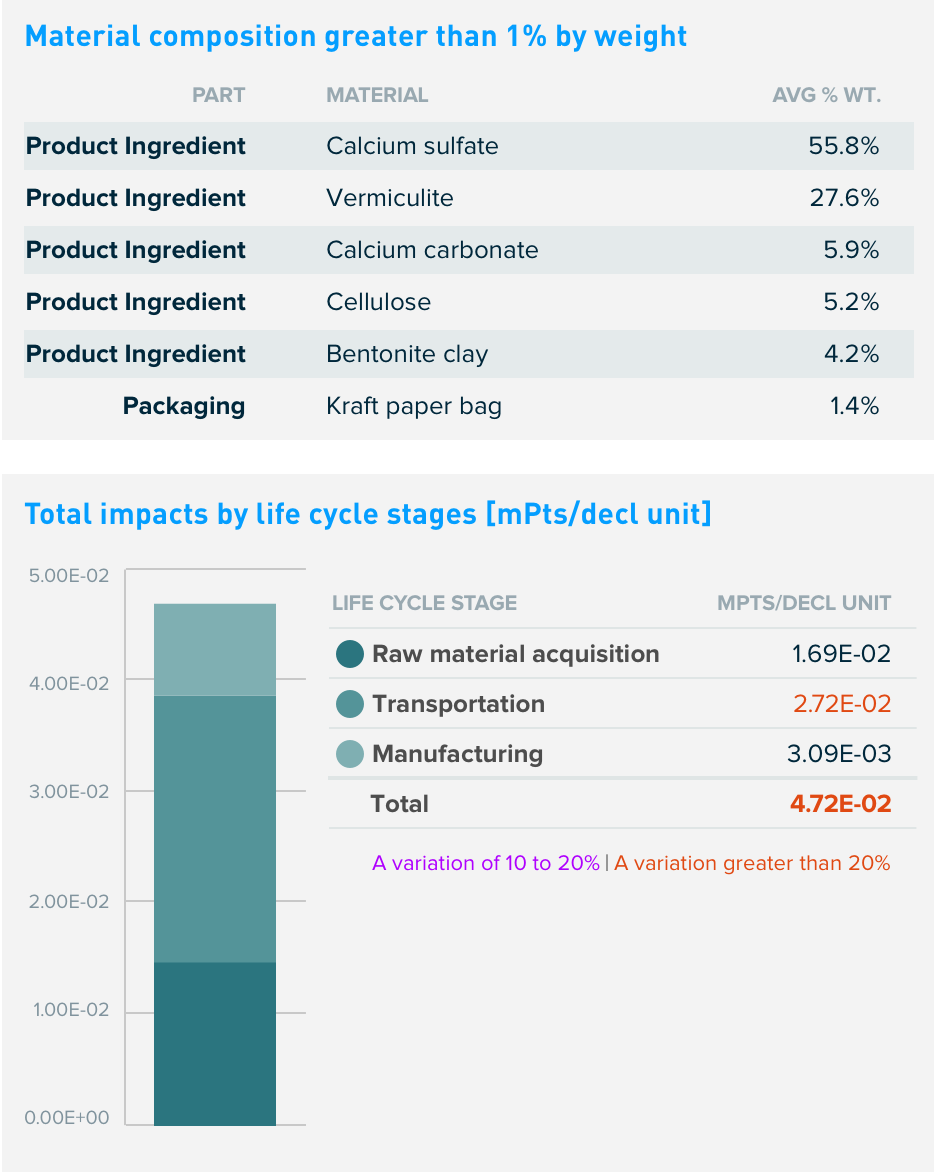

Results represent the weighted average using production volumes for the products covered. Variations of specific products for differences of 10–20% against the average are indicated in purple; differences greater than 20% are indicated in red. A difference greater than 10% is considered significant.

Isolatek minimizes its waste portfolio by employing a variety of efforts, including the reuse of recycling of spent materials where feasible.

Isolatek offers the most thermally efficient materials on the market, meaning less material is needed to complete a project.

LCA results

| Life cycle stage | Raw material acquisition | Transportation | Manufacturing | Total |

|

Information modules: Included | Excluded |

A1 Raw Materials | A2 Transportation | A3 Manufacturing | A1-A3 Total |

|

|

|

SM Single Score

Learn about SM Single Score results| Impacts per declared unit | 1.69E-02 mPts | 2.72E-02 mPts | 3.09E-03 mPts | 4.72E-02 mPts |

| Materials or processes contributing >20% to total impacts in each life cycle stage | CAFCO® 300 Series raw material production. | Truck and rail transportation used to transport raw materials to manufacturing site. | Energy and ancillary materials required to make the passive fire protection product. | Sum of the single point scores. |

TRACI v2.1 results per declared unit

- A variation of 10 to 20%

- |

- A variation greater than 20%

| Life cycle stage | Raw material acquisition | Transportation | Manufacturing | Total |

Ecological damage

Human health damage

Additional environmental information

| Impact category | Unit | ||||

| Ecotoxicity | CTUe Comparative Toxic Units of Ecotoxicity Ecotoxicity causes negative impacts to ecological receptors and, indirectly, to human receptors through the impacts to the ecosystem. |

1.50E+02 | 1.13E+03 | 1.23E+01 | 1.30E+03 |

| Fossil fuel depletion | MJ, LHV Mega Joule, lower heating value Fossil fuel depletion is the surplus energy to extract minerals and fossil fuels. |

5.55E+02 | 5.83E+02 | 1.23E+02 | 1.26E+03 |

References

LCA Background Report

Isolatek Products LCA (public version), Isolatek 2019. SimaPro Analyst 8.5.2.0, EcoInvent 3.1, 2.2 database.

PCR

ASTM PCR for Spray-Applied Fire Resistive Materials; Version 1.0, February 2022. PCR review conducted by Thomas Gloria, PhD (chair, [email protected]); Jeffrey Gould; and Karl Houser.

ISO 14025, “Sustainability in buildings and civil engineering works -- Core rules for environmental product declarations of construction products and services".

Independent external verification of the declaration and data, according to ISO 14025.

Download PDF SM Transparency Report/Material Health Overview, which includes the additional EPD content required by the ASTM Environment PCR.

Download PDF SM Transparency Report/Material Health Overview, which includes the additional EPD content required by the ASTM Environment PCR.

"Transparency Reports™ / environmental product declarations enable purchasers and users to compare the potential environmental performance of products on a life cycle basis. They are designed to present information transparently to make the limitations of comparability more understandable. TRs/EPDs of products that conform to the same PCR and include the same life cycle stages, but are made by different manufacturers, may not sufficiently align to support direct comparisons. They therefore, cannot be used as comparative assertions unless the conditions defined in ISO 14025 Section 6.7.2. ‘Requirements for Comparability’ are satisfied." EPDs from different programs (using different PCR) may not be comparable. TRs/EPDs cannot be compared if they do not have the same functional unit, reference service life, and building service life.

SM Transparency Report (EPD)

SM Transparency Report (EPD)