How we make it greener CAFCO® 400 & 400 AC

Reuse of recycled spent materials

Isolatek uses recycled cellulose in the production of the CAFCO® 400 Series products. CAFCO 400 contains up to 10% recycled cellulose.

Isolatek collaborates with vendors to provide neutral products that minimize environmental impact, conserves energy, reduces and diverts waste, and are sustainable.

These vendors, where possible, are strategically located in close proximity to our manufacturing facilities which minimized transportation costs.

Regional Manufacturing

Isolatek makes a point to minimize energy in our plants, buildings and processes in order to conserve supplies, and minimize consumption of natural resources, especially non-renewable resources.

Optimized and recycled packaging

CAFCO 400 Series products are packaged in recyclable kraft paper bags and shipped on wood pallets that can be reused or recycled.

Energy use optimization

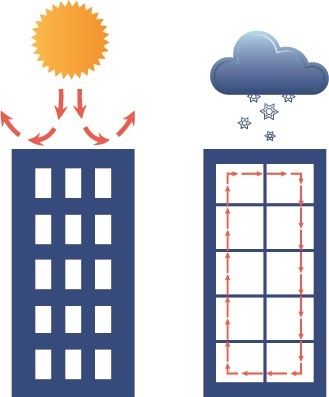

Isolatek’s materials also provide both NRC (Noise Reduction Coefficient) values and Thermal Resistance (R) values which allow for the reduction of the amount of energy needed for climate control, and reduce the need for additional materials required for soundproofing within the building envelope.

Extended set products are available that eliminates daily wash out, reducing clean water consumption and construction waste.

Reduced water use

Isolatek's materials are designed to use the least amount of water during the installation process, which results in less consumption of natural resources.

Durability

Although Isolatek's Applied Fireproofing products are designed to last the lifetime of the building, the end life of the product is generally the result of a rehabilitation, which may require removal and replacement of the Applied Fireproofing materials. The removal depends upon the degree of the rehabilitation. Otherwise, the end life of the material is based on the end life of the structure in its entirety. The material is then processed along with the remainder of the structure, primarily as landfill material.

SM Transparency Report (EPD)

SM Transparency Report (EPD)